.

If you have any comments, observations, or questions about what you read here, remember you can always Contact Me

All content included on this site such as text, graphics and images is protected by U.S and international copyright law.

The compilation of all content on this site is the exclusive property of the site copyright holder.

Maple syrup is A) natural; B) locavore food; C) organic; D) all of the above. Pretty much all of the above I would think, especially for the backyard, hobby maple syrup operator. Locavore - difficult to get more local than your own backyard. Don't know anyone who is fertilizing or otherwise treating their woodlot. And maple syrup is definitely additive-free. It's just boiled to evaporate water and concentrate the 2% sugar of the sap to something around 66%.

Earlier this month I went to the maple syrup event at th Howell Living History Farm. They're not a commercial business but in an average year they make about 50 gallons of maple syrup. Today I'm going down the road to a neighbor's sugar shack, where he'll be giving a presentation to some members of the Tohickon Garden Club. "Please remember to dress warmly and wear warm boots." the reminder message said." It has been cold enough the last two days that I don't think we will see too much mud. Looking forward to seeing you tomorrow. It should be fun!"

Sap rises in the Spring, when nights are still below freezing but daytime temperatures are higher. Sunny days increase the flow of sap. Last year was a great maple sap into syrup year, this one - not so good. It has been bitter cold, peculiarly warm, then cold again, and with lots of snow that makes it difficult to get into the woods. Still and all, today is not too bitterly cold, the evaporator will be well stoked with wood to boil the sap, and a good time will be had by all. Let's go.

John is dressed for the weather too: heavy sweater, wool overshirt, hat, fingerless gloves. He's also warmed by his enthusiasm for making maple syrup and explaining all about the process to an attentive audience. That would be us.

Ever the gracious host he's swept out the sugar shack and laid a table with refreshments for us. Tea, a delightful Assam / Earl Grey blend (2:1) made with maple sap! It was delicious. If anyone wanted it sweeter there was a small jug of this season's maple syrup. Not so much for the tea but we each took a spoon and dipped it into the syrup for a taste. Lovely. After I was done playing mother - pouring tea and passing around cookies

we all sat down, interested and enthusiastic, to listen to what John had to say. He described the necessary equipment - taps, buckets, evaporator, and more. He's a tinkerer and backyard mechanic at heart so his sugar shack was mostly built with lumber from someone's disassembled deck given away on Freecycle, a barrel stove to heat the evaporator from a metal drum and a stove kit, and a previous evaporator pan had been a deaccessioned restaurant sink, now replaced with a "proper," purchased evaporator pan. He's used metal spiles

but just last year began using these modern, recently developed plastic spiles with a tiny internal ball that at night shuts off the sap flow when it is likely to freeze. At 40 cents apiece they're cheap, and, in his opinion, better than the traditional metal spiles too. An 8-inch diameter tree gets one tap, larger trees can have a couple. Trees are given a year off after the year they are tapped. How much sap? The yield is about 10 gallons a tree, but that's variable not only on weather conditions but also the individual tree. And tapping stops when the trees begin to swell their buds as the sap, acquiring a yellowish tinge from it's earlier water-clear, develops an off taste.

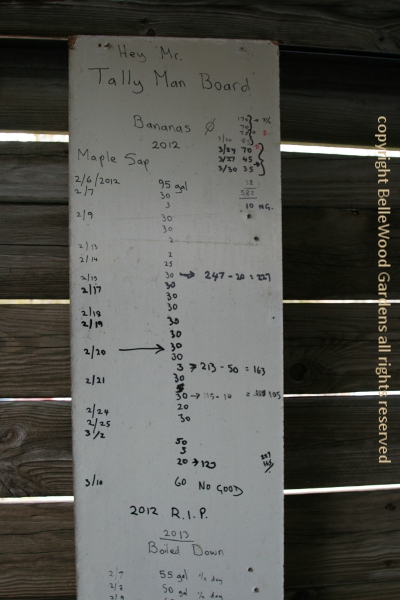

John keeps a tally board of how much sap he collected when, and how much syrup is made from it. In 2012, shown here, he began tapping trees in early February and by March 10 the sap was buddy. Clearly, 2014 is a later season.

The door to the firebox is open a crack so we can see the glowing, fiery heat that is bringing the sap to a boil and driving off the water as steam.

.

Sap dribbles in at the top, is warmed by a pre-heater, the coil of copper tubing around the chimney, before slowly flowing into the evaporator pan. Otherwise, the addition of cold sap would bring the evaporator off the boil.

There are several ways to decide when the maple sap is concentrated into maple syrup. Temperature is one method, and 219 degrees Fahrenheit is the magic number. John prefers to use a hydrometer calibrated for a saccharometer, measuring the density of sugar in a liquid.

Of course the big attraction was a visit to a real, operating sugar shack and see the evaporator seething away. In addition, John had a program on his laptop computer with the images displayed on a monitor he'd set up. Pictures of other sugar shacks, other equipment, and even images and an explanation of how to identify sugar maples by their flowers, leaves, and seeds.

Who knows, maybe next year some of us will be inspired to tap our own sugar maples.

Back to Top

Back to March 2014